Silicone Rubber Sheet For Solar Laminator

| Product Details | |

|---|---|

| Brand | Deer Hunter |

| Serial Number | The 5th-lite Gen |

| Country of Origin | China |

| Certificate | SGS, ROHS |

| Payment & Shipping Terms | |

|---|---|

| Price Quote | To be agreed |

| Minimum Order | 1 sqm |

| Average Delivery Time | 5-7days |

| Payment Method | T/T, L/C, Paypal, Credit Card, West union, etc. |

| Package Details | Woven bags, Wooden cases, Pallets |

| Ability to Supply | 100000 sqm per month |

Silicone Rubber Sheet - an irreplaceable element in solar photovoltaic modules Lamination

* Because high quality materials make the difference

Silicone sheeting is an essential component of the lamination process of solar modules. China Deer Hunter is providing solar rubber sheets with more advantages as below:

- resistance to high temperatures

- outstanding chemical resistance

- long-term flexibility

- excellent elasticity

- constant quality thanks to their internal quality management

- extra large available up to 3500 mm

- different material thicknesses

- durability results in longer machine running times and thus shorter set-up times

In the process of solar photovoltaic panel’s lamination, the panel manufacturers encapsulate all components with ethylene-vinyl acetate (EVA) adhesive film to ensure that module layers remain secure. That will cause high heat to melt the EVA (typically 145-155°C). That’s why those makers need our flexible, resilient, and durable silicone rubber sheeting membranes designed for use in the solar laminators to provide compression on the PV panes in repeated cycles.

Deer Hunter has worked in partnership with the foremost solar laminator manufacturers to develop silicone rubber membranes that meet the specific requirements of PV module manufacturing. Here it is our great honour to introduce “Then 5th-lite Silicone Sheeting” for solar PV panels lamination.

The 5th-lite Gen silicone sheeting is an exclusive laminate produced from a unique pressed composition giving extended life in solar panel production.

It has an EVA resistant fluorine laminated surface with additional fabric reinforcement.

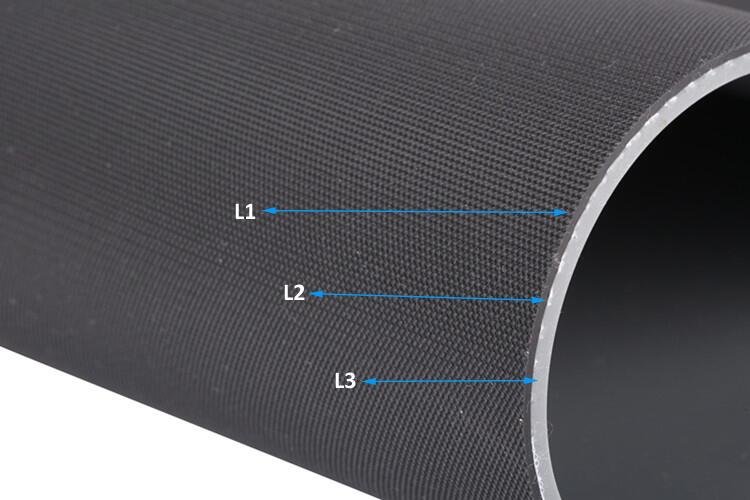

Structure

L1# Black EVA resistant hybrid – working layer

L2# 1 Ply premium aramid fabric reinforcement

L3# Grey silicone – buffering layer

This brand new model gives users many benefits including :

* Recommended operating temperature: +250°C

* Anti-ageing + acid & alkali resistance

* Extended life – more than 8,000 / 10,000 cycles

* Special hybrid covering layer bonded onto silicone backing

* Inseparable layers

* Special layer resistance to corrosive eva outgassing

Technical Data:

Material | Silicone/Hybrid | |

Color | Grey/Black | |

Surface | Smooth/Textured | |

Reinforcing Layer | 1 Ply Premium Grade Aramid Fabric | |

Hardness | EVA Resistant Working Surface (Black Hybrid) | Buffering Surface (Grey Silicone) |

70+/-2 Shore A | 60+/-2 Shore A | |

Density | 1.95 ± 0.05g/cm3 | 1.25 ± 0.05g/cm3 |

Tensile Strength | 14MPa | 8.5MPa |

Tear Strength | 45N/mm | 30N/mm |

Temperature resistance | 250°C | 250°C |

Elongation | 600% | 180% |

Compression Set | 4% | 4% |

Resilience | 8% | 25% |

* And you can also download the technical data sheet as below:

Technical Data Sheet – The 5th-lite Generation Silicone Rubber Sheet |

Deer Hunter – Asia’s leading manufacturer for special silicone gel sheets for solar PV panels encapsulation in the renewable energy market. We can choose from a variety of laminator brands and types. Depending on the solar module production line requirements, a solar panel laminator from 3S, Meier, Bürkle, Komax, Electro Solar, or others is integrated.

Standard dimensions of silicone rubber sheet for solar laminator

- Length – Any

- Width – Max up to 3500mm

- Material Thickness – 4mm or 3mm

- Widely-used sizes are from our customers’ regular purchasing orders.

| Country | Sizes |

| USA | 4mm * 2550 * 6550 4mm * 2850 * 5550 4mm * 3050 * 4850 |

| Mexico | 4mm * 2600 * 4100 4mm * 2730 * 5870 4mm * 3200 * 5200 |

| Morocco | 4mm * 2000 * 2400 |

| India | 4mm * 2550 * 5720 4mm * 2575 * 4675 |

| Jordan | 4mm * 2760 * 4960 |

| Turkey | 4mm * 2650 * 4730 4mm * 2750 * 4100 4mm * 2850 * 5050 3mm * 3110 * 4460 |

| Vietnam | 4mm * 2800 * 4100 |

| Philippines | 4mm * 2500 * 4100 |

| South Korea | 3mm * 2755 * 4925 |

| Germany | 4mm * 2410 * 4500 |

| Poland | 4mm * 2200 * 3700 4mm * 2700 * 4500 |

Package

To confirm there will be no damage in transport. Deer Hunter logistic staff provide strong package service for our customers.

1: Quantity below 5rolls

usually put inside cardboard tubes

2: Quantity more than 5rolls

We prefer to put all rolls in wooden cases

RFQ

1: What’s the best silicone sheeting for photovoltaic modules lamination?

A: This is really a vital question and can be best discussed together face-to-face. There is no one answer that is right for everybody. There are many determining factors that can affect the choice of silicone diaphragm for example type of encapsulant, the composition of the modules, size of the modules, the brand of laminator, and budget constraints, etc.

2: How long should the silicone rubber sheeting last?

A: Commonly our data shows that The 2nd Gen – 4,000cycles + The 5th Gen – up to 10,000 cycles. As there are a number of variables beyond our direct control, it is very difficult to “guarantee” an exact cycle life.

3: Does color or surface finish have any impact on membrane performance?

A: Based on feedback from customers worldwide, we can see no advantage or disadvantage of different colors, or indeed surface finish. Actually, colors are now used to differentiate between suppliers.

4: What can we do to extend the life of our solar laminator rubber sheets?

A: Consider protecting it with a layer of PTFE sheet between the modules and the membrane. We have several options for this.

5: Can you do tailor-made products?

A: We are very willing to research and develop a kind of silicone rubber sheet for your special requests.

You'd Like To Learn More

Become Our Partner

We are well prepared to work with you tegether!

No matter who you are and what you do, a wholesaler, distributor or end-user, we are always looking out for new partnership chances. Submit an application today and our sales team will get back to you as soon as possible within 24 hours and help you select the right item you want.

- fullchance100

- 0086 13823789007

- exporting@cndeerhunter.com